Granite remains one of the most trusted materials specified in commercial environments. Chosen for its durability, longevity, and premium appearance, it is widely used in high-traffic interior and exterior spaces. Its strength and resistance to wear make it particularly well-suited to areas that experience constant foot traffic and demanding conditions. However, even a material as robust as granite can present challenges when safety is closely examined.

In environments where moisture is present, whether through cleaning regimes, rainfall or barefoot use, slip resistance becomes a key consideration. Improving underfoot performance without compromising the appearance or integrity of the stone is therefore an important part of responsible surface specification and long-term maintenance.

This article explores how slip resistance can be improved on granite surfaces without altering appearance, and how PROGRIP can be used in public-facing environments.

Understanding Granite in Indoor and Outdoor Projects

Granite is a dense, siliceous natural stone valued for its ability to withstand heavy use over long periods of time. Indoors, it is commonly specified for entrance areas, circulation spaces, washrooms and wellness facilities, where its hard-wearing nature and relative ease of maintenance make it a practical choice. Depending on the finish, granite may be polished, honed or textured, with each responding differently to moisture and foot traffic.

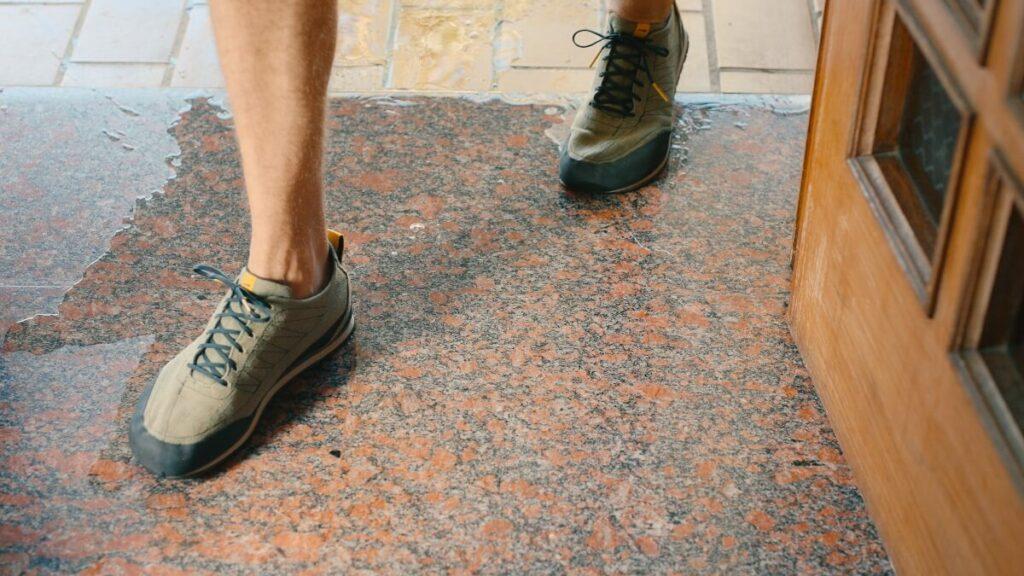

Externally, granite offers distinct benefits. Its strength and resistance to weathering allow it to perform reliably in exposed environments, including steps, ramps, thresholds and pathways. Granite copes well with rain, temperature changes and long-term environmental exposure, making it a popular choice for public access areas and transitional spaces between indoors and outdoors, while also providing visual continuity across a building.

Slip Risk Considerations

That same density and durability, however, can affect grip when granite is exposed to moisture in use. In interior commercial spaces, slip risk can arise from cleaning processes, spillages or tracked-in water, particularly on smoother finishes.

In dedicated wet environments, such as pool surrounds and spa facilities, moisture is consistently present across wider surface areas, increasing the demand for reliable underfoot performance. Externally, rainwater and surface damp can have a similar effect. As a result, granite installations in both indoor and outdoor settings often require additional consideration to balance long-term performance with safety.

Targeted Slip Resistance for Granite

PROGRIP is a professional non-slip treatment for granite and other siliceous stone surfaces where increased grip is required. Instead of sitting on the surface like a coating, it reacts with the stone itself to improve grip, without forming a film.

The process creates a microscopic texture within the surface. This is invisible to the eye and does not alter the granite’s appearance. When the surface is damp, however, the improvement in grip is noticeable underfoot, providing greater stability and confidence in use.

Because PROGRIP leaves no residues and does not alter the stone’s visual character, it is particularly well suited to public-use spaces where safety improvements must be achieved without compromising design intent.

How to Use PROGRIP on Granite Surfaces

Before full application, a test should always be carried out on an unlaid tile or an inconspicuous area to determine the correct contact time. PROGRIP begins to react after approximately 1 minute. Where required, further tests can be carried out using progressively longer contact times. Adjacent materials should be protected during this stage.

The surface must be thoroughly cleaned prior to treatment, using the appropriate FILA cleaner for the type of contamination present. For easier control, the area should be divided into sections of around 1 to 3 square metres, using joints or edges to define each section.

PROGRIP is applied using a fleece applicator or paint brush, ensuring the surface remains evenly wet with product for the full contact time. Each section should be treated using the same method and contact time to achieve consistent results. Once the contact time has elapsed, the product is removed using a liquid vacuum cleaner or with a cloth or mop and thoroughly rinsed with clean water.

After treatment, a neutralising wash is recommended using CLEANER PRO diluted to 1:200 (25 ml in 5 litres of water), applied with a white pad across the entire treated surface, then moving on to the next area.

To see how this process works in practice, watch our short video below showing PROGRIP being applied on site, step by step.

Typical Applications for PROGRIP on Granite

This treatment is commonly used in areas where granite has been selected for its durability, but where safety requirements demand improved slip resistance. Typical applications include:

- Poolside areas in leisure centres and hotels

- Spa facilities and wellness zones

- Public entrances and granite thresholds

- External stairs, ramps and walkways

- Barefoot areas such as showers and changing rooms

The product can be applied across entire surfaces or limited to specific zones where slip risk is highest, such as entrances, changes in level or areas subject to frequent moisture.

The Importance of Ongoing Maintenance

Slip resistance should not be viewed as a one-off intervention. Ongoing maintenance is vital to preserving the performance of treated granite surfaces over time.

Aggressive cleaning methods, unsuitable detergents or residue build-up can all compromise friction and reduce the effectiveness of anti-slip systems. For this reason, correct maintenance must be incorporated into the long-term care plan from the outset.

CLEANER PRO, diluted at 1:200, is recommended for routine cleaning of PROGRIP-treated granite. As a neutral cleaner, it removes dirt effectively without leaving residues or films that could reduce grip. Used consistently, it supports long-term performance while respecting the natural stone surface.

Application Responsibility and Best Practice

Likewise, correct application is essential to achieving reliable results. Contact time must be carefully controlled, as excessive exposure may affect surface appearance, including a reduction in gloss or changes in colour. The surface temperature should be between 10°C and 30°C, and treated areas should not be exposed to direct sunlight during application. Adjacent materials must be protected, particularly glass, as the product is corrosive on certain surfaces.

Safer Granite, Same Appearance

Granite remains a dependable and visually strong choice for high-traffic environments. When slip risk arises, it need not result in surface replacement or aesthetic compromise.

PROGRIP offers a professional, controlled solution for improving slip resistance on granite, addressing safety concerns while preserving the surface as it was designed to be seen. When combined with correct preparation and a suitable maintenance regime using CLEANER PRO, it forms part of a considered, system-based approach to surface safety.

For commercial projects where performance, responsibility and longevity matter, this balance is essential. Thinking about using our anti-slip treatment on a granite surface? Contact our technical team for advice on suitability, application and aftercare.