Are you struggling with stains from salts and contaminants on absorbent sensitive stones? FILA’s PW10 is your solution—this powerful sealer blocks tannins and oxides from migrating, preventing unexpectedly streaks and stains.

PW10 ‘s advanced formula ensures your surfaces stay pristine. Discover its features, benefits, and application techniques to integrate this effective treatment into your projects.

The Solution for Protecting Against Contaminants

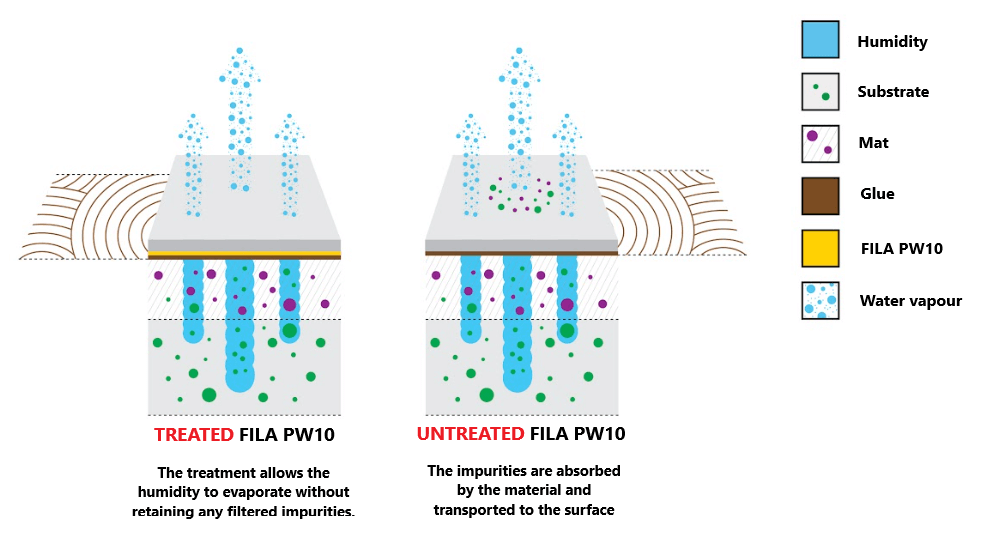

Absorbent materials like natural stone are prone to issues where impurities rise through the substrate, causing unexpected marks and discoloration in a matter of weeks.

PW10 is a water-based contaminant blocker designed for the professional treatment of absorbent materials such as granite, marble, and other agglomerates. When applied, it prevents pollutants from rising through the substrate, protecting against halos and stains.

Key Advantages of PW10

Preserves Adhesive Properties :

- Does not significantly alter the bonding characteristics of adhesives.

- Maintains integrity of the installation, ensuring strong adhesion.

- Verified reliability in various scenarios through extensive glue tests.

UV Resistance:

- UV resistant.

- Highly durable even when exposed to sunlight.

- Ensures long-term surface protection and appearance retention in outdoor environments.

Permeability:

- Allows the material to breathe.

- Facilitates water vapor escape, preventing moisture buildup.

- It promotes proper drying and curing of setting materials, which is essential for installation longevity.

Environmentally Friendly:

- It is formulated as water-based and VOC-free.

- Reduces harmful emissions, contributing to improved indoor air quality.

- Safe for both environmental sustainability and human health.

Water-Repellent and Consolidating:

- Enhances surface integrity with water-repellent properties.

- Resists water absorption, reducing the risk of damage.

- It strengthens the surface structure, preventing deterioration and extending the material’s lifespan.

By integrating these comprehensive benefits, PW10 provides superior protection against efflorescence and other contaminants and ensures that your surfaces remain durable, breathable, and environmentally friendly.

Where PW10 Can Be Used

PW10 is a versatile, water-repellent product ideal for floors and coverings. It is suitable for natural stone, terracotta, and other absorbent materials.

It forms a protective barrier that prevents contaminants from compromising surface integrity, maintaining the material’s natural breathability.

How to Apply PW10

General Instructions: The product is ready to use; no dilution is needed.

Pre-Installation Treatment (5-Side Protection)

This sealer must be applied to the back and edges of the tile to block contaminants from rising through the back and four sides of the material.

- Clean the Surface:

- Thoroughly clean the back and sides of the tile or slab, removing all dust and residue.

- Ensure the surface is dry and free of any humidity.

- Apply the Product:

- Use a large, flat paintbrush or an airless sprayer to apply an even coat of PW10 to the dry surface.

- Avoid allowing the product to pool on the surface.

- Drying:

- Position the tile or slab so the four sides and back can dry completely.

- Allow the product to dry completely before installation. Drying times vary.

- 12 hours at temperatures between 68ºF and 104ºF (20ºC and 40ºC).

- 24 hours at temperatures between 50ºF and 68ºF (10ºC and 20ºC).

- Installation:

- Choose an adhesive suitable for the type of installation according to technical standards or by consulting the adhesive manufacturer.

- After the initial cleaning, complete the treatment with a water-based or solvent-based sealer suitable for the surface’s intended use.

6-Side Protection

To block contaminants from rising through the back and sides of the material and to minimize water absorption on the top of the tile in high-humidity situations. This sealer must be applied to the back, edges, and top of the tile.

- Clean the Surface:

- Clean all six sides of the tile or slab, removing dust and residue.

- Ensure the surface is dry and free of any humidity.

- Apply the Product:

- Using a large, flat paintbrush or an airless sprayer, apply an even coat of PW10 to the dry surface.

- Alternatively, immerse the material in the product for about 30 seconds.

- Remove any product residue by blotting the surface with a cloth to prevent pooling.

- Drying:

- Ensure the material dries completely before installation. Drying times vary:

- 12 hours at temperatures between 68ºF and 104ºF (20ºC and 40ºC).

- 24 hours at temperatures between 50ºF and 68ºF (10ºC and 20ºC).

- Installation:

- Select an adhesive suitable for the type of installation according to technical standards or by consulting the adhesive manufacturer.

- After initial cleaning, complete the surface treatment with a solvent-based sealer suitable for the surface’s intended use.

Post-Installation Application – Surface Protection:

To minimize water absorption on the top of the tile or slab.

- Prepare the Surface:

- Ensure the surface is clean and dry before application.

- Apply the Product:

- Apply PW10 to the surface until it is saturated using a large, flat paintbrush or an airless sprayer.

- Remove any product residue by blotting the surface with a cloth.

- Drying:

- The surface dries in approximately 6 hours.

- Professional Application:

- Application with an airless sprayer should only be carried out by professionals equipped with appropriate personal protective equipment (PPE) as described in the safety data sheet.

Precautions

Do not apply PW10 on polished surfaces.

Certifications for PW10

Indoor Air Comfort Gold

PW10 is certified with the prestigious Indoor Air Comfort Gold , ensuring low VOC emissions and supporting healthier indoor environments. This certification is recognized by major green building programs such as LEED and BREEAM, making this sealer an excellent choice for sustainable construction projects.

Key Features of the Indoor Air Comfort Gold Certification:

- Compliance with Standards: PW10 meets stringent international requirements for low VOC emissions, ensuring excellent indoor air quality.

- Health and Safety: The certification confirms that this sealer is safe for indoor use, significantly reducing harmful emissions.

- Support for Green Building Programs: The certification is recognized by LEED and BREEAM, helping projects earn credits and comply with sustainability standards.

Advantages for Construction Projects:

- Eco-Friendly: Using PW10 aligns with sustainable building practices, reinforcing environmental responsibility.

- Streamlined Certification: The Indoor Air Comfort Gold certification simplifies earning LEED and BREEAM credits.

- Enhanced Protection: This sealer protects against efflorescence while supporting environmental and health standards.

With its Indoor Air Comfort Gold certification, PW10 ensures superior contaminant protection and support for sustainable building practices.

Elevate Your Project’s Quality with PW10

With FILA’s PW10 , you can confidently use natural stone in your projects without worrying about stains. For further assistance or inquiries, feel free to contact our team . We’re here to help you achieve successful outcomes.

No related posts.