In the world of surfaces, few materials walk the line between old-school utility and modern design quite like terrazzo. Once a go-to choice for public buildings and grocery stores, this material is now a bold design choice in high-end homes, boutique hotels, and urban developments across the United States. Durable, characterful, and increasingly sustainable, it’s a material that contractors are seeing specified more and more frequently.

So, what do you need to know when working with terrazzo today? In this article, we’ll unpack its history, varieties, challenges, and performance features, with a few expert care tips woven in along the way.

A Brief History

From Stores to Statement Floors

Many experienced contractors will remember seeing terrazzo underfoot in banks, grocery stores, hospitals, and schools. Hard-wearing, easy to mop, and practically indestructible, it was a logical fit for high-traffic public spaces. However, decorative flooring is experiencing a revival — not as a background surface, but as a focal point.

Designers are specifying this material for residential kitchens, restaurant bars, boutique hotel lobbies, and even staircases and feature walls. It’s not unusual to see this medium paired with brass inlays, bold pigment blends, or even custom aggregates that match the surrounding décor.

This resurgence has also reignited interest in its historic and cultural cousins, especially in regions where decorative cement flooring has long played a central role.

Cuban Tiles: A Heritage of Color and Craft

- Made from Portland cement, marble powder, and natural pigments, Cuban tiles are dense and decorative, with a smooth finish.

- Pressed hydraulically and cured — not glazed or fired — they became popular in the 1920s–1950s, especially in Florida and Puerto Rico.

- While not strictly terrazzo, these decorative cement tiles have helped inspire many of today’s cement-based designs.

Why Terrazzo Is Trending

For designers and clients alike, this application ticks a lot of boxes:

- Customizable: Aggregates can be chosen to match a project’s palette, branding, or story.

- Durable: With the proper installation and sealer, this system can outlast most other surfaces.

- Seamless: Especially in poured applications, it offers a smooth, joint-free treatment that is hygienic and elegant.

- Low Maintenance: Once sealed, cleaning is simple.

Where Terrazzo Works Best

Whether it’s a residential home or commercial build, terrazzo delivers style and strength in equal measure. Here are some of the most in-demand applications:

- Residential Interiors: Kitchens, entryways, bathrooms, and utility rooms benefit from the material’s seamless, easy-to-clean makeup.

- Commercial Projects: Hotels, airports, and office lobbies often use this flooring type for its durability under foot traffic and aesthetic flexibility.

- Countertops and Furniture: Precast options are on the rise in kitchens and bathrooms, offering a custom alternative to traditional stone.

- Outdoor Use: While epoxy blends aren’t suitable for exterior environments due to UV sensitivity, cement-based terrazzo can be used outdoors in mild climates or sheltered areas, provided the substrate is sound and the surface is properly sealed and maintained.

Types of Terrazzo to Know

One of the key things to understand about this surface is that it isn’t a one-size-fits-all solution. There are several varieties to work with, each with its technical considerations:

Cementitious

The traditional choice, especially for restoration work or thick-set floors. Made from cement, marble, or recycled stone chips. Requires longer curing times and is more porous. It may require additional protection and maintenance due to its higher absorbency. According to insights from our trade network, cement-based options are less favored due to maintenance challenges and installation complexities.

Epoxy (Resin-Based)

A commonly specified choice for modern builds. As confirmed by our U.S. contacts, this resin-based format is now the dominant terrazzo type in many commercial projects. Thinner, lighter, and allows for a broader color range. It’s made using a resin binder with natural stone chips, offering excellent design flexibility and resilience in interior settings. Best suited for commercial and residential interiors; not recommended for areas exposed to direct sunlight or UV light.

Precast

Used for sinks, countertops, stair treads, and furniture. Installed like other modular stone surfaces.

Bio-Based (Bio-Polymer)

A newer, sustainable category using plant-based resins and recycled content. Referred to by our contacts as a “sustainable, natural” option, it’s growing in popularity for green builds and low-VOC environments. Durabella Biopolymer Terrazzo floors, for example, offer a tough, joint-free surface that’s easy to maintain — but like all flooring, they still need regular care to stay at their best. We’ll be covering biopolymer terrazzo maintenance in more detail in our next blog post.

Installation Considerations

While terrazzo is known for its longevity and aesthetic flexibility, getting the installation right is key to long-term performance. Each type comes with its own set of requirements:

- Cementitious varieties need a solid substrate and control joints to handle movement. It also has a longer curing time and may require a thicker build-up, making it best suited to ground-floor or new-build projects.

- Epoxy, on the other hand, is lighter and thinner, often poured at just a quarter of an inch thick. It cures quickly and allows for a broader color range, but must be installed over a perfectly dry, crack-free substrate. Moisture can lead to failures if not adequately mitigated.

- Precast behaves more like natural stone during installation. Templates are often required for vanities, furniture pieces, or stair treads, and accurate fitting is crucial to prevent visible joins or shadow lines.

On another note, this material is often compared to polished marble in terms of care and maintenance. As one of our commercial partners suggests, “It’s like an expensive polished marble: you must seal before grouting, clean with a neutral cleaner, and use a wax for enhanced stain resistance and appearance.”

That advice sums it up nicely. But for contractors working on the ground, it’s worth digging into the details of what can go wrong — and how to get it right from the outset.

What Can Go Wrong — and How to Prevent It

Terrazzo is a durable surface, but it’s not bulletproof. Understanding how it behaves during and after installation is key to avoiding costly mistakes. Here’s what to watch for on site.

Moisture Absorption

During installation, unsealed surfaces — especially unpolished materials like cement-based terrazzo — can absorb moisture, resulting in white marks or bonding issues. Apply PRW200 before grouting to reduce absorption and staining, even on matte or non-glossy finishes. Alternatively, CONTRACTOR’S CHOICE (available in gallon format) can be used as a pre-grout treatment to protect against moisture and help ensure proper bonding.

Acid Etching (Major Risk Factor)

Likewise, terrazzo is also highly sensitive to acid. Even mild acids, such as vinegar, citrus juice, wine, or bleach, can cause dull spots and permanent etching, especially on cement-based mixes. Avoid acidic cleaners and spills wherever possible, particularly in kitchens and hospitality settings. For routine cleaning, we recommend using a pH-neutral product, such as STONECLEAN.

Staining from Spills or Oils

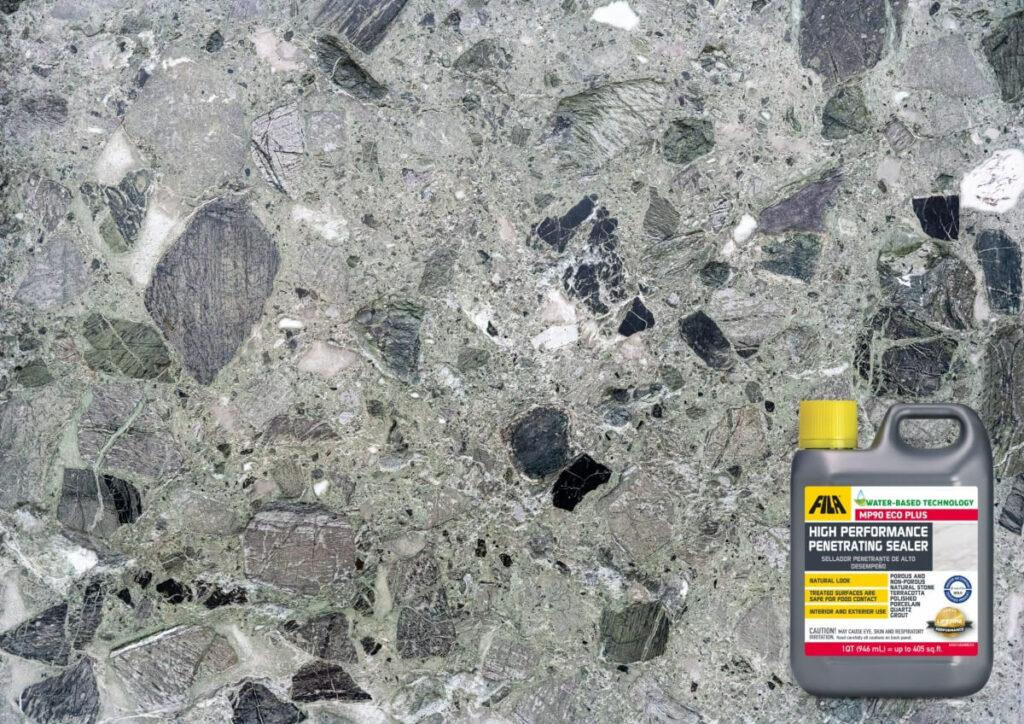

Unsealed terrazzo can absorb liquids like oil or grease, leading to deep stains that are difficult to remove. Apply MP90 ECO PLUS, a water-based, food-safe sealer that helps prevent staining without changing the surface appearance.

Optional Step: Add a Wax Finish for Extra Protection

Four to five hours after applying MP90 ECO PLUS, you can finish the surface with a protective wax such as FILA’s MATT (Matte) or SATIN (Satin). This creates a physical coating between the surface and potential stains.

Wax, however, is not an impregnator — it’s a topical layer, which means things like soap scum or grease will attack the wax before reaching the terrazzo itself. It also gives installers and designers more control over the final appearance of the flooring.

Pros

- Additional stain protection

- More control over the final finish (matte or satin)

- Helps make everyday cleaning easier

Cons

- Needs reapplying every 45 days

- Less commonly used, so some clients may not be familiar with the option

We’ll go into more detail about wax maintenance and reapplication tips in our next blog post.

Incorrect Cleaning

General-purpose cleaners can dull the surface over time. We recommend sticking with STONECLEAN, FILA’s trusted pH-neutral solution for ongoing care.

Heavy Soiling or Grease Buildup (Use with Caution)

In commercial settings or after construction, this surface can accumulate deep-set grime that standard cleaners cannot remove. PS87 is effective for lifting oil, grease, and stubborn residues, but proceed with care.

Important note from our trade clients: When working with epoxy or resin-based varieties, alkaline products like PS87 can cause the bonding agent to deteriorate, resulting in porosity, pitting, and a dulled finish. Always test in a discreet area, avoid prolonged contact, and rinse thoroughly after use.

Sustainability and Terrazzo

Terrazzo is gaining momentum not only for its aesthetic appeal and endurance but also for its eco-conscious advantages. Here’s why:

- Recycled Content: Many mixes utilize recycled aggregates, including glass, stone, and concrete, thereby significantly reducing waste.

- Lower VOCs: Epoxy blends have improved over the years, with many modern formulations producing fewer volatile organic compounds.

- Bio-Based Options: As mentioned, the bio-polymer type takes it a step further by using plant-based resins in place of petroleum-based binders.

- Waste Reduction: Precast elements are manufactured off-site, reducing installation waste and increasing efficiency.

The right surface treatments also matter — water-based, low-VOC options like MP90 ECO PLUS support green credentials without compromising performance.

Getting It Right Together: Designers, Contractors & Suppliers

Beyond product knowledge, collaboration is key to a smooth installation, especially on design-led projects. Aligning on layout, materials, and maintenance early on will help avoid costly surprises. Here are a few helpful pointers:

- Get clarity on layout early: Whether the project calls for brass inlays, color-blocked sections, or specific chip distribution, confirm all visual details before the pour or order stage. These elements often affect lead times and prep work.

- Discuss maintenance upfront: Suggesting appropriate sealers and cleaners during the design phase ensures that expectations match the material’s real-world performance.

- Request samples if needed: Precast pieces and custom mixes may appear differently in situ than they do on paper. A small mock-up or sample board can help avoid disappointment down the line.

When contractors, designers, and suppliers work in sync, it leads to a smoother install and a finish everyone is proud to sign off on.

Why It Pays to Know Terrazzo

Terrazzo is on the rise — and for a good reason. Contractors who understand how to work with it confidently are setting themselves apart in a growing market. Get the foundations right — from smart sealing to proper cleaning — and you’ll deliver results that look better, last longer, and keep those stakeholders coming back.

Next month, we’ll share the full FILA care cycle for this application: from installation prep to long-term maintenance. Until then, if you have any questions about treatments or product recommendations, feel free to contact our team — we are always happy to help.